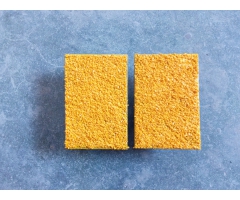

skid resistant coating

>

industrial equipment overhaul channel anti skid coatings

industrial equipment overhaul channel anti skid coatings

BD75N Industrial equipment overhaul channel and metal staris special anti skid resistant coating.

Product usage:

Mainly used in the paving of industrial equipment overhaul channel,metal stairs skid resistant coating.Especially used in the preparation of anti skid coatings on metal road surface,stair passageway etc.

Packaging specification of BD75N industrial road bridge anti wear skid resistant coatings:

Two-component,packed in a plastic drum,10Kg/drum.

We could offer professional customized packaging and sub-package services based on users’ requirements.

Performance features of BD75N anti wearing skid resistant compound industrial road bridge repairing coating:

1.Two components room temperature curing high polymer coating

2.Curing speed is fast,with high bonding strength,the cured product is abrasion wearing resistant,high and low temperature resistant.

3.With good bonding force to for both metal and cement etc.

4.Coating has high cohesion strength,with good aging resistant performance,has flame resistance.

How to use:

1.Make the adhesive tape be bonding on the periphery of pending-construction part,do the sand blasting,grinding treatment on the surface of

pending-construction part,in order to protecting no needing construction part from pollution.

2.Clean the pending-bonding surface,make sure the pending-bonding surface be clean and dry.

3.According to the weight ratio A:B=10:1,make the B component pour into the A component,it can be put into using after mixing and stirring uniformly.

4.This adhesive can be brush coating or roller coating,brush coating for 2 times,the time interval for each time brush coating is about 30 min,

waiting for 10 min after the second brush coating,sprinkle a thin layer of abrasive material particle,then brush coating a layer of topcoat,curing

for 24 hours at room temperature,we don’t suggest construction when the temperature is below 0 degree,the curing time will prolong to 48

hours at the temperature of 0-10 degree.

5.The mixing mass ratio of the topcoat: This product(BD75N skid resistant coating) : acetic ether=3:1,mix them uniformly.

6.Remove the adhesive tape and finish the construction.

Performance index:

| Project | Index | Testing standard | |

| Appearance | Uniform viscous liquid,without impurities | visual inspection | |

| Viscosity£¨Pa·s,25¡æ£© | 4.0±0.6 | GB/T2794-1995 | |

| Density (20¡æ g/cm3 ) | 1.21 | GB1033-1986 | |

| Surface drying time(min) | 30¡«50 | GB/7123-1986 | |

| weather resistance (UV irradiation for 7 days) | Without change | GB/T1766-1992 | |

| Shore D Hardness | 80 | GB/10807-1989 | |

| Tensile strength (MPa) | 49.7 | GB/T1040-1992 | |

| Shear strength (MPa) | 16.6 | GB/T2791-1995 | |

| Working temperature (¡æ) | -60¡«200 | ||

Notes:

1.Weigh the main agent and curing agent according to the specified mixing ratio,make sure to mix and stir it uniformly.

2.Please use it in time after configuring adhesive,in order to avoid causing the waste after the adhesive thickening.

3.Ethyl acetate is the thinning agent of this product.

4.The coating without curing is afraid of water,try to avoid outside construction in rainy day.

5.The skid resistant coating without curing completely is forbidden to walk.

Storage

This product is the common chemicals,should pay attention to water resistant,fire prevention in the process of transportation and storage,

sealed storage in a cool and dry place,the storage period is 12 months.

Construction protection measure:

1.Wear protective masks,protective glasses and rubber gloves.

2.Washing hands with soap before eating,drinking or smoking.

3.The health hazard after touching with:a few people may have skin allergy phenomenon,seek medical advice in time and avoid contacting

with this product again.Stick to the skin accidentally by rubber material,should use the ethyl acetate to wipe it up,then flush it with clear water.

Splash into the eyes accidentally,should rinse with water immediately and go to a doctor.

4.Residual glue liquid cured product is the non-toxic harmless organic solid,but there may be a poison gas during burning,non-professional

personnel shall not do combustion disposal.

Fire prevention measure:

Ethyl acetate catch fire should choose dry powder fire extinguishing,rubber material catch fire can use dry powder,sand(can also use

construction use abrasive material),or use the non-chemical fiber fabric to cover and swat fast.

------·Ö¸ôÏß----------------------------

abrasion wear

resistant coating

resistant coating

crusher backing

compound

compound

anti corrosion

resistant coating

resistant coating

slurry pump

repair coating

repair coating

industrial ceramic

epoxy adhesive

epoxy adhesive

rubber liquid

coating

coating

thermal heat

insulation coating

insulation coating

skid resistant

coating

coating

heat conduction

coating

coating

thermal conductive

adhesive

adhesive

high temperature

resistant adhesive

resistant adhesive

high strength

structural adhesive

structural adhesive

industrial repair

agent

agent

rubber metal

bonding adhesive

bonding adhesive

elastic flexible

adhesive

adhesive

high temperature

anti seizure compound

anti seizure compound

high temperature seize

resistant agent

resistant agent

bearing anti wear

fastening adhesive

fastening adhesive